Steam Happens #22 The Evolution of a Model

Steam Turbine

(21 June 2012)

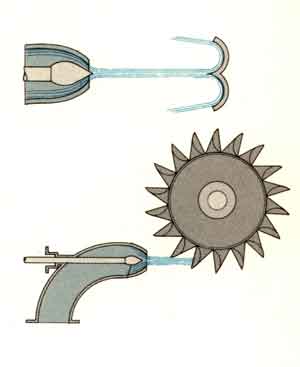

Steam turbines are generally one of three types:

Impulse turbines like the Pelton where

The force of water from a stationary nozzle strikes the "buckets"

directly pushing the buckets downstream and rotating the turbine wheel (rotor):

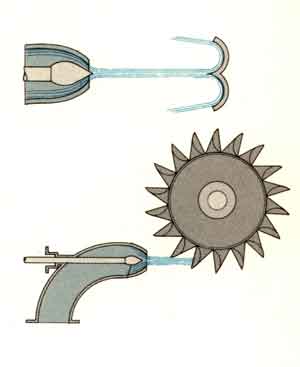

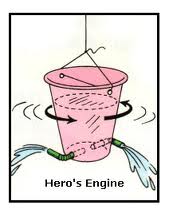

Reaction turbines operate like the Hero engine where

the fluid (or steam) is ejected from spinning nozzles on the rotor

causing it to "react" by rotating in the opposite direction of the ejected

fluid:

The third type, Combination turbines, usually have both an impulse and a reaction component.

The rotor that I designed is of this type. The

initial part of the blade receives the impulse from a stationary nozzle

while the remaining portion of the blade has an airfoil shape and produces a

reaction within the disc.

Click on the image below and watch a video of the rotor being milled on my home-made CNC mill.

Note link to CAD and CNC files below

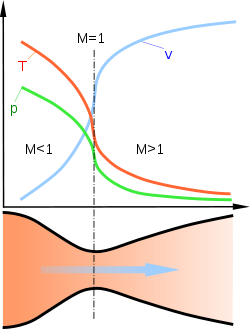

Most turbines depend on de Laval-type

nozzles that change the the steam flow much like a solid fuel rocket nozzle,

increasing steam velocity while lowering the steam's temperature and pressure.

The de Laval nozzle has a converging cone, a throat, and a diverging cone. It works like this:

Since the turbine is to be used in a model boat it is directly connected to a 24 Volt DC motor running as a generator.

In this way, the power produced by the

turbine can be used to run an electric motor connected to the prop with the

remainder being stored in a set of batteries.

If the turbine is connected to a constant output boiler the boat can continue to

run when the boiler shuts down. Very handy!

Here's an April 2012 updated version of a video of an HO trolley running on the

turbine that I took to Cabin Fever in January, 2012.

It was running on compressed air and ran continuously for about 14 hours. Click

on the picture below.

Here's a video of the rotor running on live steam in May 2011. Click on the picture below.

For the full article subscribe to Steamboating Magazine and ask for a copy of the May/June 2012 issue.

If you have access to a cnc

mill, intend to build a turbine using this disc, and you are willing to keep in

contact with me regarding your progress, I will email you a copy of the article

in the .PDF format at no cost.

Please remember that your project may not use the G-code for commercial

purposes and must include a comment line attributing the original code to me

(Earl Morse) via Steamboating Magazine.

Email E_J_Morse@roadrunner.com

For more information about impulse vs. reaction turbines and general information click the references below:

Technical info on blade design

Wikipedia's history of turbines

More on marine propulsion from Wiki

In addition, there are a good number of FREE ebooks on old steam turbines available through Amozon, Google Books, Openlibrary.org, Project Gutenberg etc.

OpenLibrary, for example, shows 55 free books most can be read in pdf format with very clear illustrations, at various levels of sophistication.

DOWNLOADABLE FILES FOR CNC MACHINISTS:

please credit Earl Morse in all communication and sharing

Please note that G-code is for personal, one-off use, only. Not for commercial use!

You may have to right click on links below and choose "save

as" option to save in "downloads".

Open with appropriate software.

G code for turbine disc. as .txt file. MUST BE EDITED FOR YOUR CNC MILL

.dwg FILE FOR TURBINE DISC (some layers not correctly labeled but work fine)

If you don't have CAD software for viewing either dwg or dfx files Click

here to

download free viewing software

that allows rotation and close examination of drawings.