Tweaking your "D" valve for Reduced Steam Consumption

Steam Happens 27

Tweaking your "D" valve for Reduced Steam Consumption

Steam Happens 27

Scotch Yoke Animation

Click here for my movie showing a Scotch Yoke water pump

*****************************************************************

Note that at 50% of travel crankpin is always at 90 degrees to stroke axis

***********************************************************************************************************************

Note that the longer the stroke the larger the angularity issue

********************************************************************************************************************

Note that longer connecting rods tend to lessen angularity issues

***************************************************************************************************************

Note that introducing cutoff produces angularity issues that are unequal on the outstroke and return stroke

**************************************************************************************************************

Diagram 5: Comparing Scotch Yoke and Connecting Rod Engine for Angularity Error

Note that, unlike the connecting rod engine, the crank motion in a Scotch Yoke engine always produces equal angularity for the down-stroke

and return-stroke

*************************************************************************************************************

.jpg)

****************************************************************************************************************************************

.jpg)

*************************************************************************************************************

***************************Tweaking the HasBrouck #1 Engine's "D" valve for Improved Efficiency and Smoother Running.

An Example that will give you some practice before you modify your own engine.

*******************************************************************************************

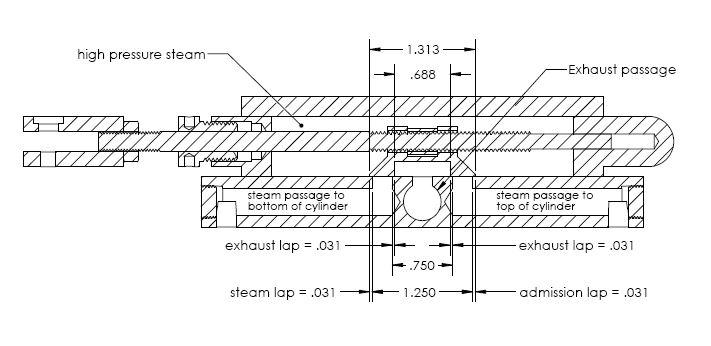

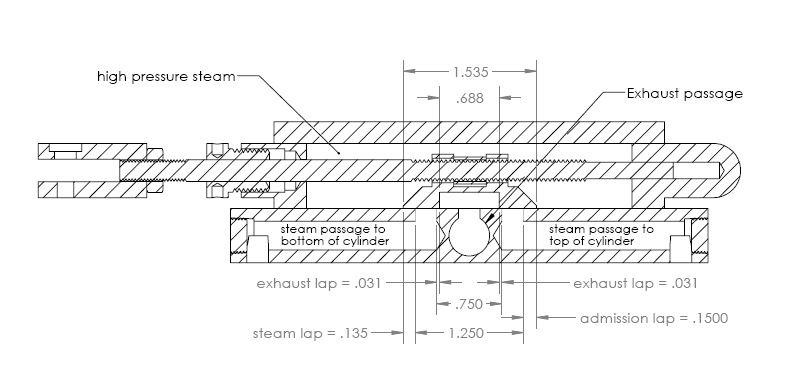

FIGURE 1

: HasBrouck #1 Steam Chest & D Valve**************************************************************************************************************

FIGURE 2: HasBrouck #1 Original D Valve Dimensions

**************************************************************************

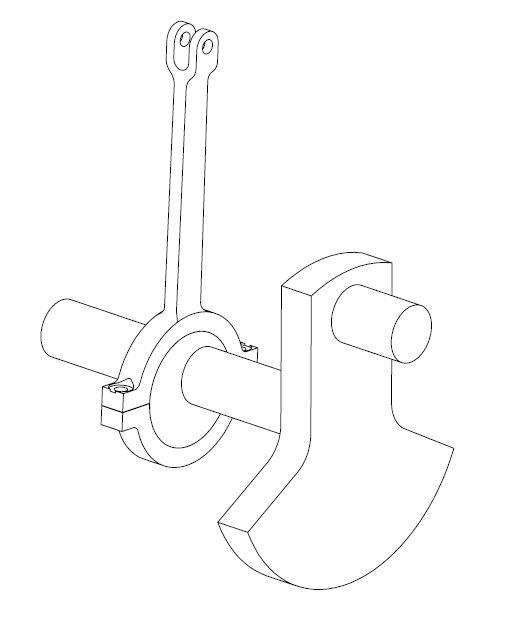

FIGURE 3: Crankpin and typical eccentric position

******************************************************************************

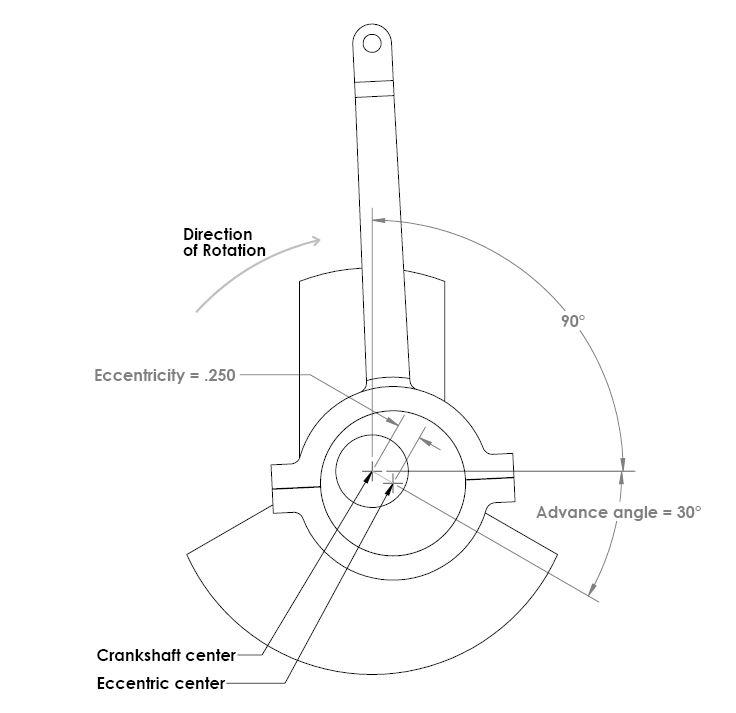

FIGURE 4: Eccentric position showing typical advance angle

****************************************************************************

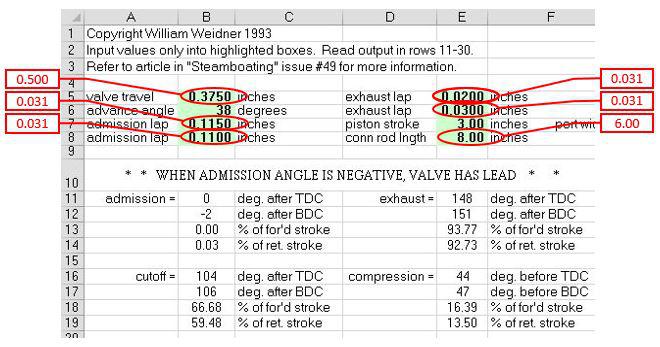

LET THE TWEAKING BEGIN: The valve design software, Valvegr2.xls, can be found for download at

http://earlmorse.org/steamboa.html

****************************************************************************

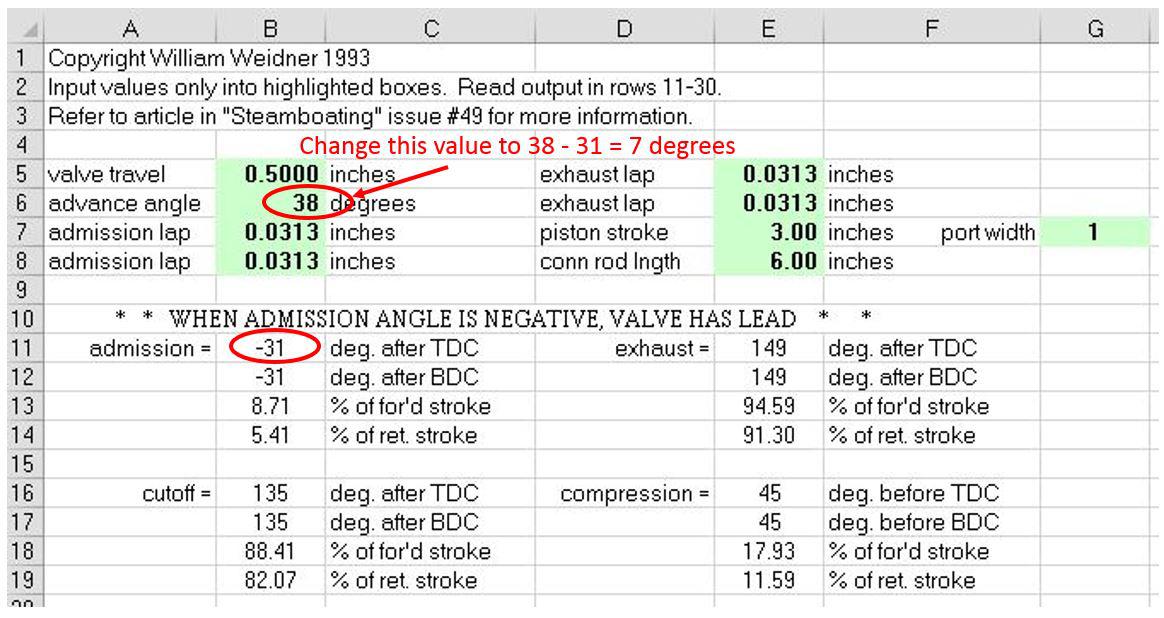

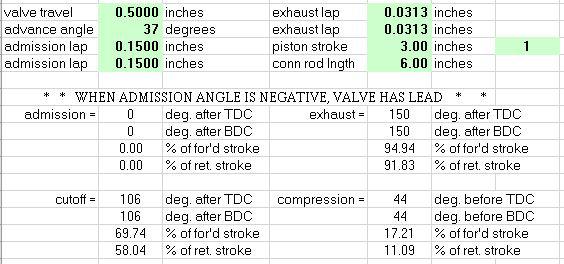

FIGURE 5

: Inserting HasBrouck's Original Dimensions into Will's Tweaking SoftwareThe original HasBrouck dimensions (in red) replace the original (black) included in the software.

Top value (e.g. admission lap = 0.031) refers to downstroke, the value beneath it (also 0.031) refers

to the return stroke. Note that the original software's advance angle is left at 38 degrees for the

time being.

*******************************************************************************

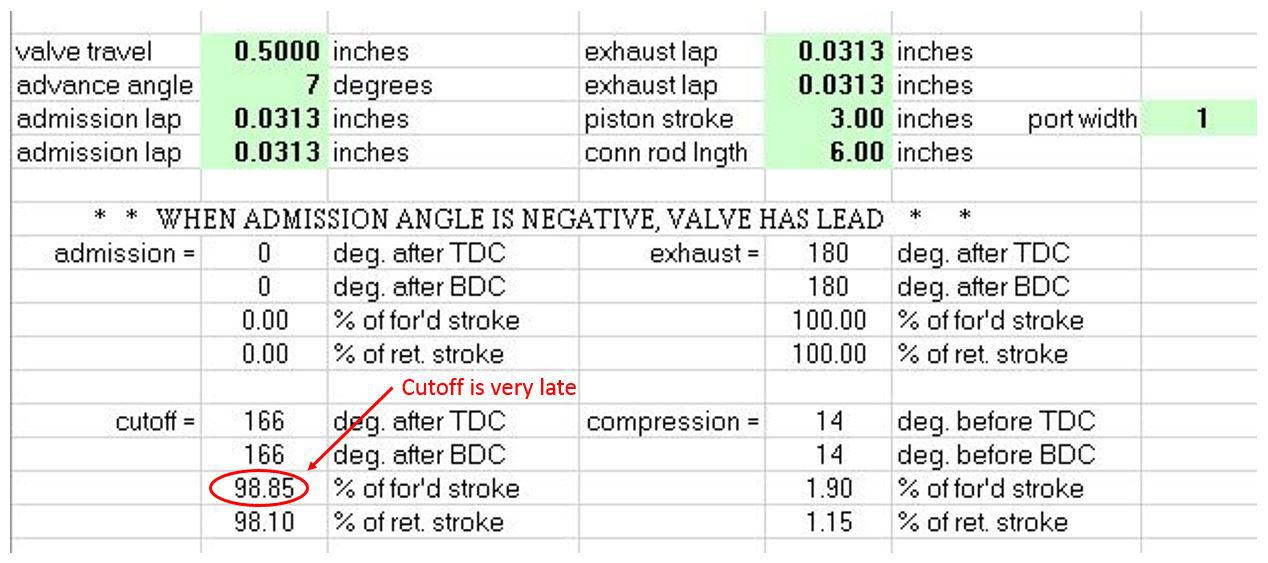

FIGURE 6

: This results in an admission of -31 degrees Before TDC. To get the admission to 0 degrees38 is added to the -31 resulting in an advance angle of 7 degrees (see below).

This produces TDC and BDC admissions of 0 degrees.

********************************************************************************

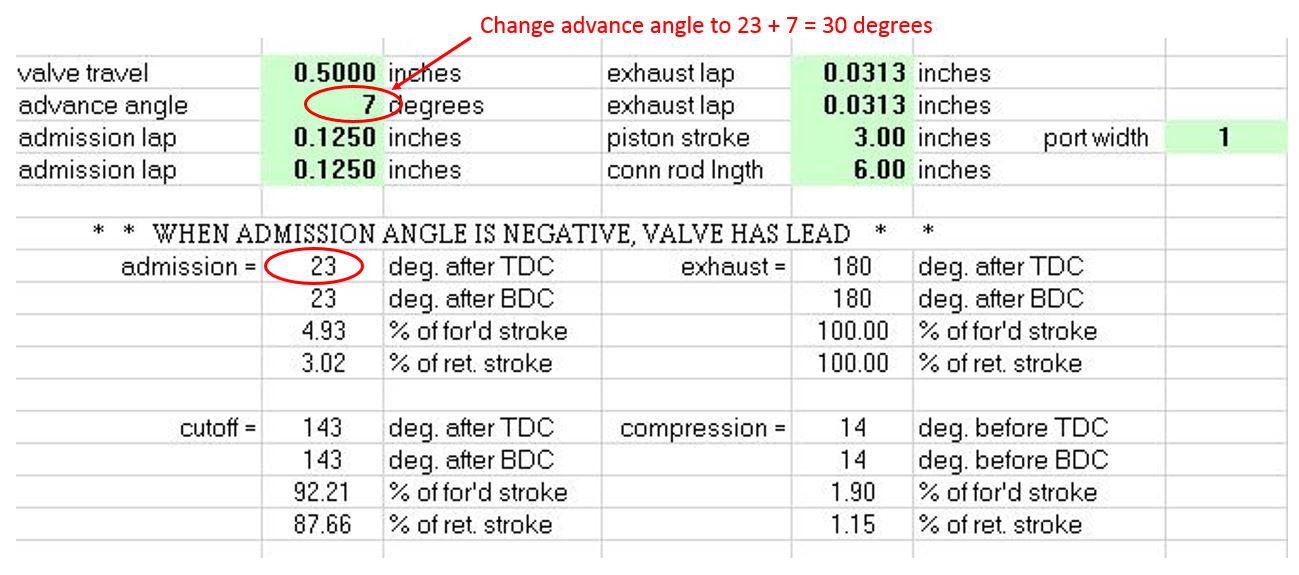

FIGURE 7

: Zeroing admission to TDC and BDC shows almost no cut-off in original HasBrouck specs.***********************************************************************************

FIGURE 8

: Adding to the original HasBrouck the lap specs of 0.031 to try a lap of 0.125 inchesbut now the admissions are 23 degrees after TDC and BDC. So we'll add 23 degrees to 7

degrees to bring admissions to TDC and BDC and make the advance angle 30 degrees.

(within the typical advance range of 30 to 38 degrees)

************************************************************************************

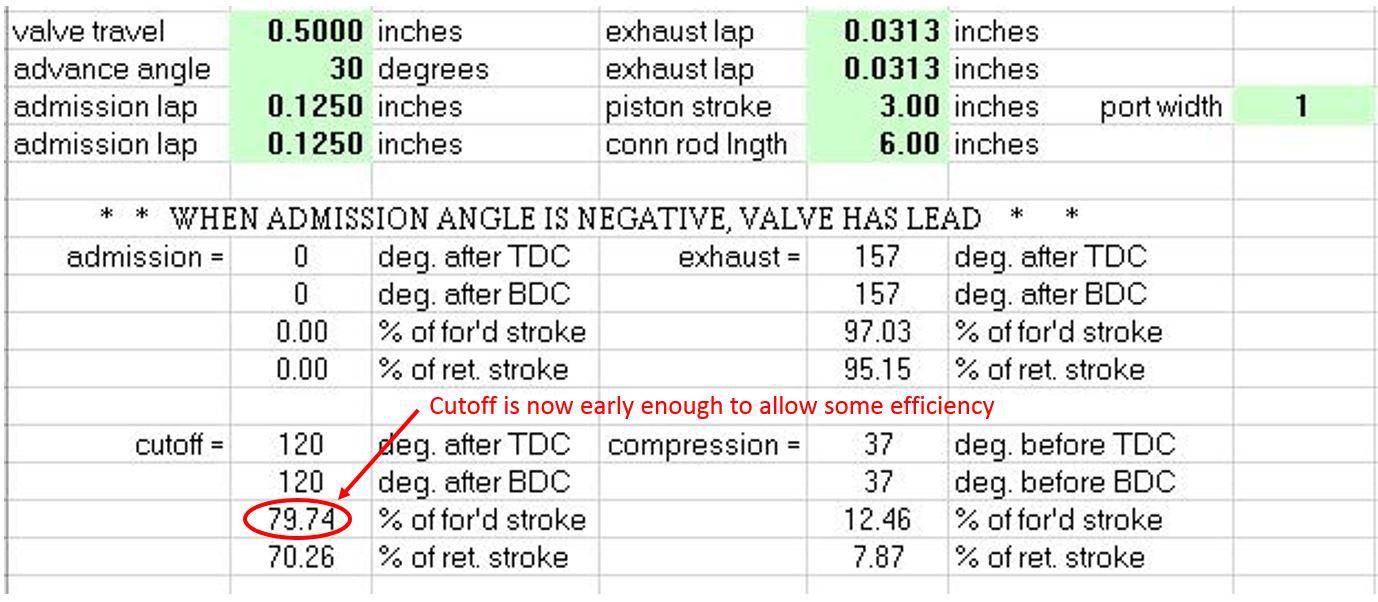

FIGURE 9

: First tweaking brings cut-offs to the 70-80% range**********************************************************************************

FIGURE 10

: Adding a bit to the advance angle and the laps produces better results, but now the returncut-off is too much.

***********************************************************************************

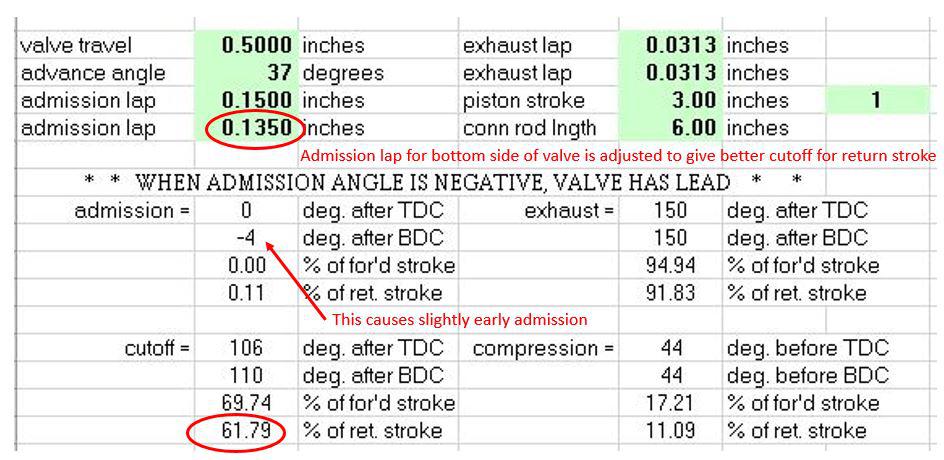

FIGURE 11

: Changing the return admission lap to 0.135 inches brings the return cut-off to nearly62% of travel. It turns out that -4 degrees early admission of the return stroke is OK.

Having a -4 to -2 degree early admission on the return stroke makes for an easy starting and

smooth running. This is because a very small amount of piston movement represents a large

amount of rotation at BDC (because of angularity), which effectively gives a large amount of

leverage over the steam force on the piston.

************************************************************************************

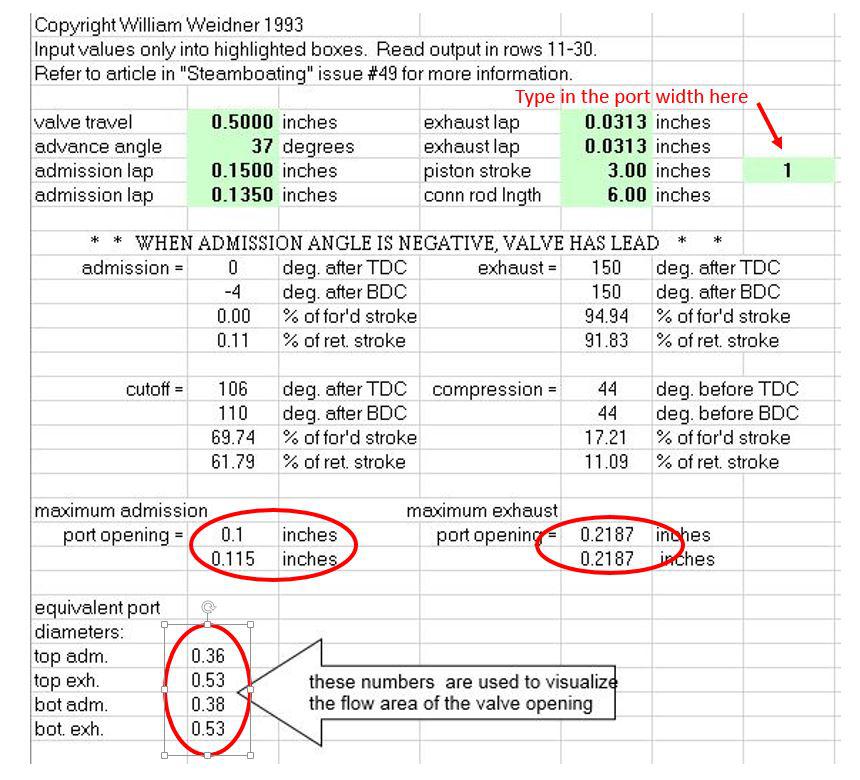

FIGURE 12

: Visualizing port opening sizes.BTW, Will likes a bit of exhaust lap (0.031 inches in this case) in his engines since it

"cushions" piston direction reversal, quiets slightly worn bearings a bit, and helps reduce

the use of steam in the next incoming charge. Exhaust lap is less important in small engines

and/or engines with sealed ball bearings. It's your call.

****************************************************************************

FIGURE 13 HasBrouck #1 Modified Dimensions After Tweaking